| Availability: | |

|---|---|

| Quantity: | |

Guangshu (Guangzhou) Xindai (Taiwan) KND (Beijing)

The fully enclosed appearance is generous and the structure is user-friendly. Easy to operate and use. Main shaft grease lubrication, maintenance-free maintenance-free;

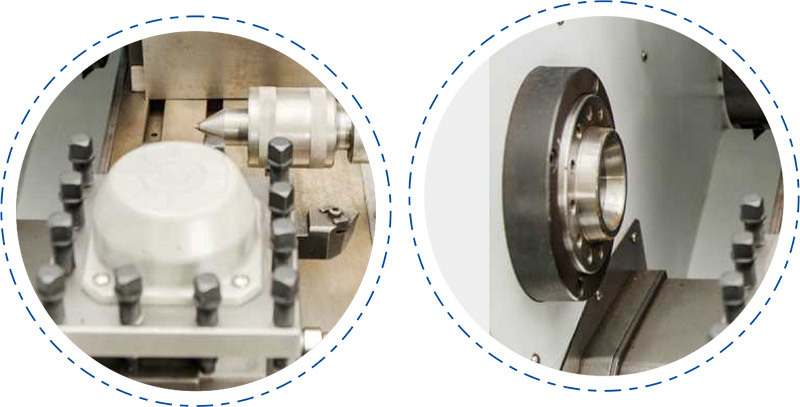

Linear guide configuration, standard with angular contact shaft bearing, low noise, high speed, long life, dust/water resistant dust/water resistant design;

Large stroke in the X-direction allows for the installation of a larger number of tools and accessories. The Z-directional spindle is mounted in the centre for even force application.

This machine tool is most suitable for processing fields: aviation equipment, optical precision parts, auto parts, electronic connectors, advanced button accessories, small valves, watch parts, threaded joints, etc. It has particularly good processing of small parts, precision parts and non-ferrous metals.

Small hardware parts: steel, stainless steel, copper and aluminum

Short shaft, disc parts: precision shaft pins, bushings, spindles, rings

Precision thread: high-grade threaded joint, precision spindle lock cap, tooth compound nut

| Project | unit | Reference data | |

| Work Fan | Max. turning diameter | mm | Ф350 |

| Max.machining diameter of the pallet | mm | Ф150 | |

| Max. machining diameter | mm | Ф350 | |

| Max. tailstock processing length | mm | 330 | |

| itinerary | Max. Stroke X-axis | mm | 290 |

| Max. Stroke Z-axis | mm | 320 | |

| Main axis | Spindle through hole diameter | mm | Ф49 |

| Pull tube through hole diameter | mm | Ф40 | |

| Feed | Fast moving speed X-axis | mm/min | 20000 |

| Fast moving speed Z axis | mm/min | 20000 | |

| other | Spindle speed range | r/min | 50-3000/140 spindle unit 4500 |

| Clamping method | — | Pneumatic/hydraulic | |

| Tool holder type | — | Row knife holder/electric knife holder | |

| Main motor power | Kw | 4 | |

| Tailstock | — | M14 | |

| Dimensions(L*W*H) | mm | 1920x1310x1780 | |

| Weight (about) | T | 1.4 | |

Note: "/" indicates that this configuration is optional According to customer needs, machine configuration is optional

MB: +86-189-0657-0891