Guangshu (Guangzhou) Xindai (Taiwan) KND (Beijing)

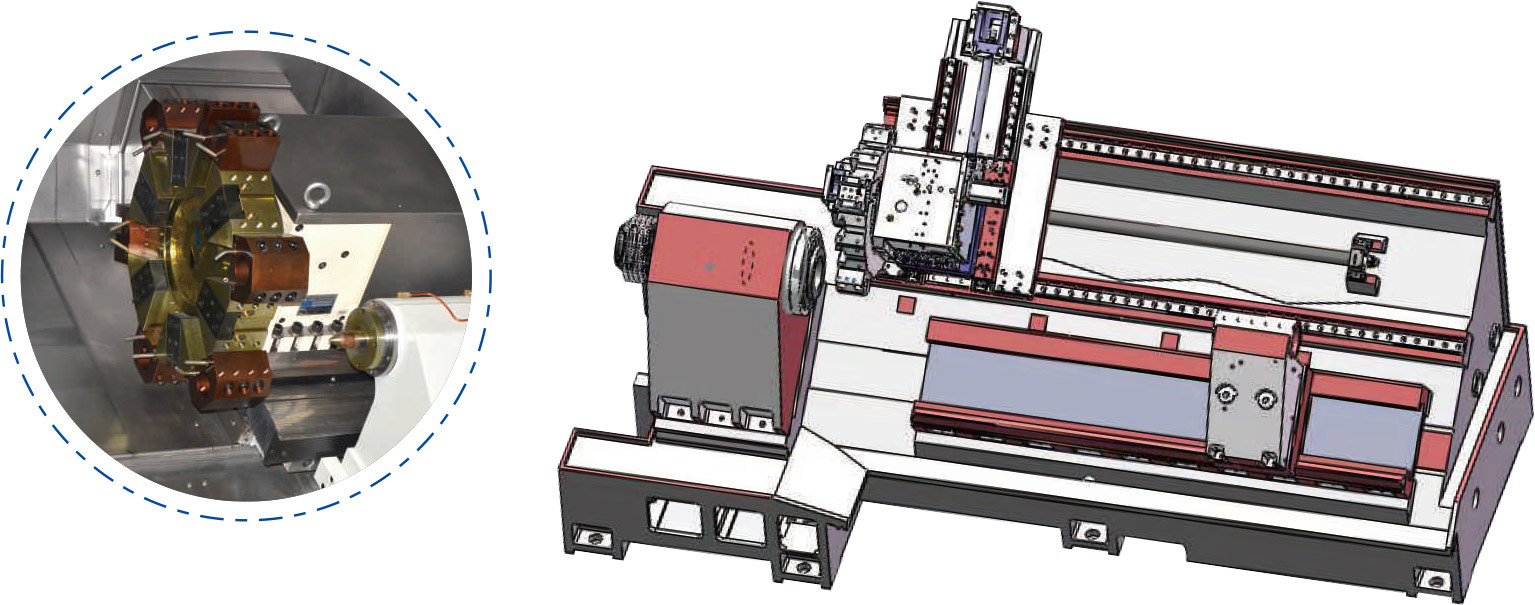

1、Bed base is integral casting, inclined bed It is conducive to workpiece up and down and chip discharge.

2、X \ Z direction are used imported line rail, reduce the machine tool wear and tear, the oversized preload of the line rail reduces the guide rail clearance, increasing the machining accuracy.

3、The whole series adopt spindle unit

4、Turret, hydraulic chuck, hydraulic tailstock, improve The versatility and automation of the machine.

5、Fully protected machine tools to improve water and chip resistance. The machine is fully protected against water and chips.

This machine tool is most suitable for processing fields; aviation equipment, auto parts,valves, non-ferrous metals, disc parts, large bearing rings, precision long thick shafts.

| Project | unit | Reference data | |

| Work Fan | Max. turning diameter | mm | Ф650 |

| Max.machining diameter of the pallet | mm | Ф360 | |

| Max. machining diameter | mm | Ф550 | |

| itinerary | Max. Stroke X-axis | mm | 300 |

| Max. Stroke Z-axis | mm | 1100 | |

| Main axis | Spindle through hole diameter | mm | A2-8/Ф86 |

| Pull tube through hole diameter | mm | Ф75 | |

| Feed | Fast moving speed X-axis | mm/min | 20000 |

| Fast moving speed Z axis | mm/min | 20000 | |

| other | Spindle speed range | r/min | 50-3500 |

| Clamping method | — | 12" hydraulic chuck | |

| Tool holder type | — | 125-12station hydraulic servo turret | |

| Main motor power | Kw | 15Kw servo main motor | |

| Tailstock | — | Hydraulic Mt5 | |

| Dimensions(L*W*H) | mm | 3990x2100x2220 | |

| Weight (about) | T | Approx.5.5 | |

Note: "/" indicates that this configuration is optional According to customer needs, machine configuration is optional

MB: +86-189-0657-0891