Guangshu (Guangzhou) Xindai (Taiwan) KND (Beijing)

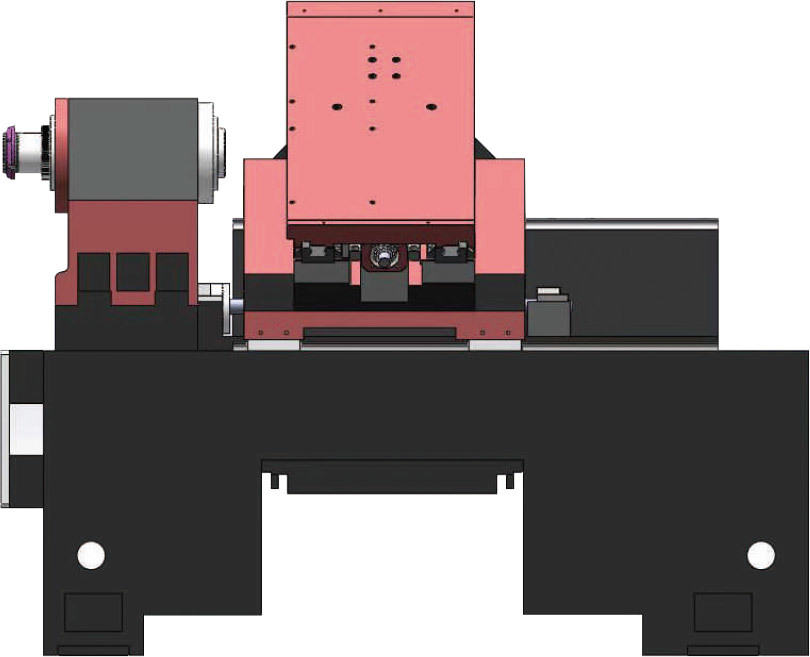

Suitable for: bearing rings, discs, short shafts and other high-precision heavy cutting

1, high speed, high precision hydraulic rotary cylinder, precision collet and high rigidity precision power chuck configuration, to improve the ability to cut tough materials and powerful cutting.

2, 35 ° large tilt bed, conducive to workpiece up and down and chip discharge.

3、Both directions use super heavy-duty ball linear guide Both have strong rigidity and reduce the wear and tear of the machine It can guarantee the machining accuracy of the machine for a long time.

4、Both directions use large ball screws and large The large ball screw support bearings ensure the long-term stability of the machine.

5、Large stroke row of tool holders, the number of tool positions, so that repeatable tool change error to the minimum, high speed and accurate tool change The machine saves a lot of processing time.

6、Large volume base, convenient for manual cleaning of iron chips.

7、Full protection machine tool, improve the waterproof and chip-proof ability. The machine is fully protected against water and chips.

The precision heavy cutting function improves production efficiency at the customer's production site. In the processing of high-hardness products represented by the bearing ring industry and requiring high precision, it plays an important role in improving production efficiency through rational mechanical structure. Zhenjiang has mature production application solutions to help customers, including bearing inner ring and outer ring processing.

| Project | unit | Reference data | |

| Work Fan | Max. turning diameter | mm | Ф600 |

| Max.machining diameter of the pallet | mm | Ф160 | |

| Max. machining diameter | mm | Ф580 | |

| itinerary | Max. Stroke X-axis | mm | 400 |

| Max. Stroke Z-axis | mm | 420 (jaw face to drag board surface) | |

| Main axis | Spindle through hole diameter | mm | 62 Mechanical spindle/*Mid 56 (Mid 170 spindle unit) |

| Pull tube through hole diameter | mm | 52 mechanical spindle/*medium 46 (medium 170 spindle unit) | |

| Feed | Fast moving speed X-axis | mm/min | 20000 |

| Fast moving speed Z axis | mm/min | 20000 | |

| other | Spindle speed range | r/min | 50-3500 |

| Clamping method | — | Hydraulic collet chuck/hydraulic chuck (optional) | |

| Tool holder type | — | Row tool holder / 8-station turret (optional) | |

| Main motor power | Kw | 5. 5Kw servo main motor | |

| Tailstock | — | none | |

| Dimensions(L*W*H) | mm | 2200x1700x1800 | |

| Weight (about) | T | 2.6 | |

MB: +86-189-0657-0891